Quality that lasts, manufactured in Geesbrug

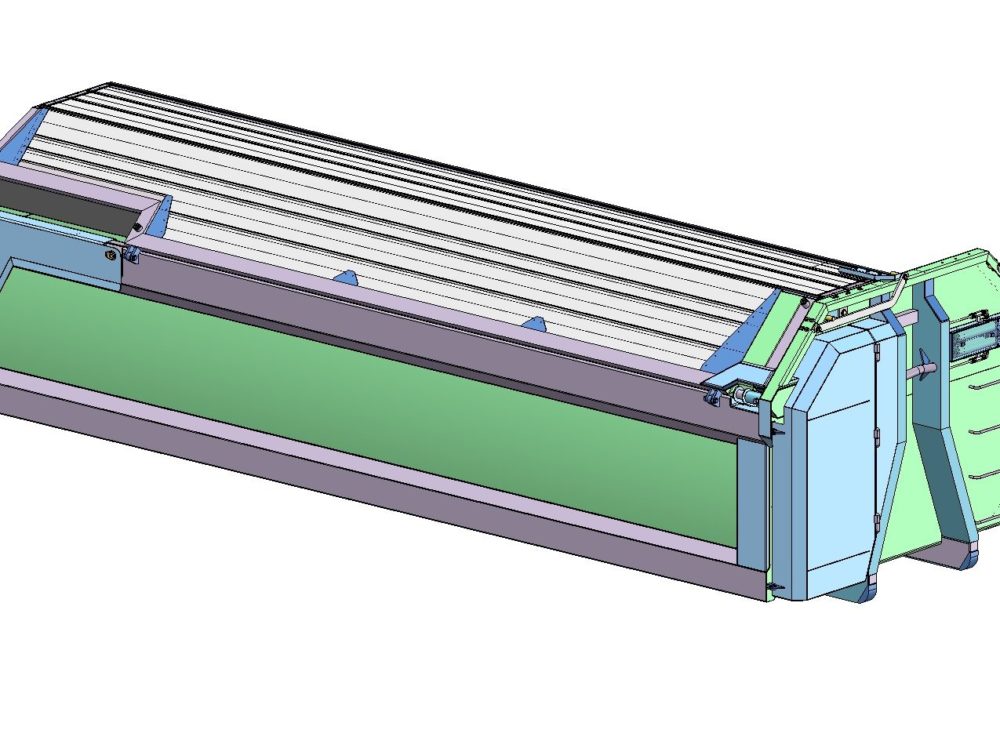

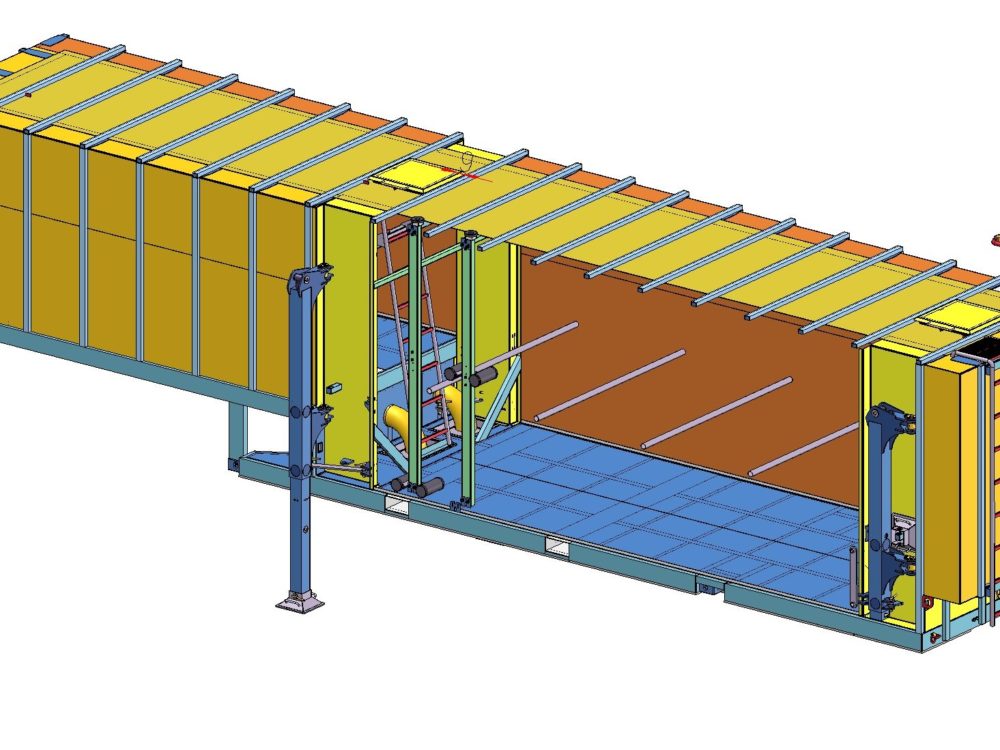

Vossebelt has been building tippers and roller containers of all kinds and in all sizes for forty years. Over the years we have expanded our range to include belt unloaders, self-developed cover systems and special constructions. From engineering through to delivery, we take care of everything ourselves at our premises in Geesbrug. As we build and deliver every product ourselves, we can guarantee exceptional quality and durability. We are able to respond quickly and flexibly to your wishes.

Management summaryModern production area for an efficient production process

In four halls, with a total area of over 5,000 m2, we work in line on various products using modern production techniques. Thanks to a fully automated sawing line, CNC shears and automated welding processes, we can make the production process as efficient as possible. Our expert employees can therefore manufacture large numbers of tippers and containers in accordance with your specifications in a short amount of time. In addition, we have been granted the ISO 14001:2015 certificate, which signifies we have a top-notch environmental management system.

Translating the order into a product

At Vossebelt we have been enthusiastically building tippers, containers and loading beds for many years – often as commissions for customers. We like short lines of communication. That is why our planning and control department has an important role to play within our company. The staff in this department translate the order for our production department, ensuring you get exactly what you asked for. Engineering and production drawings are developed using a 3D drawing package. All these drawings are linked directly to our ERP system.

Careful fitting in our spacious workshop

Tippers belong on the back of a truck or trailer chassis. At Vossebelt we therefore have a spacious workshop where we can carry out this fitting work. Our workshop is equipped with loop systems for hydraulic oil and for protective gas for welding. Various spring balancers in the workshop make our tools virtually weightless during operation. An exhaust gas extraction system also allows us to test our tippers and truck-mounted cranes in the workshop itself.

Parts and repairs

Vossebelt not only supplies complete tippers, containers, loading beds and belt unloaders – you can also come to us for parts and repairs. We hold a wide range of parts for our products in stock and can fit these for you in our workshop. Here we can also build cover systems onto existing tippers or containers. In addition, we can repair floors, replace doors and align containers or tippers. Do you have any questions? Please do not hesitate to get in touch.

Contact

Want to know more?

Feel free to contact us.

Vossebelt B.V.

Coevorderstraatweg 31

7917 PP Geesbrug

T +31 (0)524 29 14 88

KvK 04086014